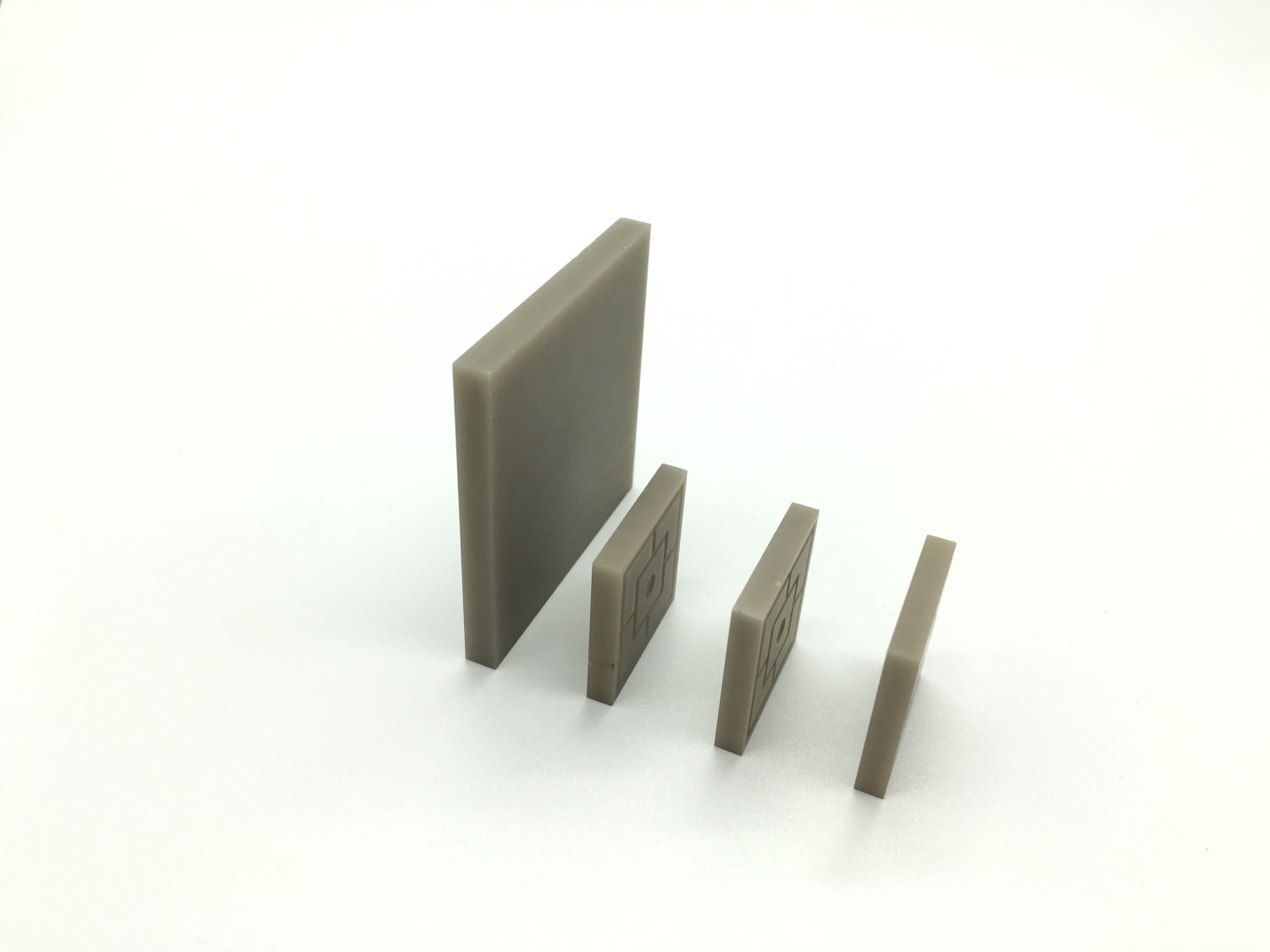

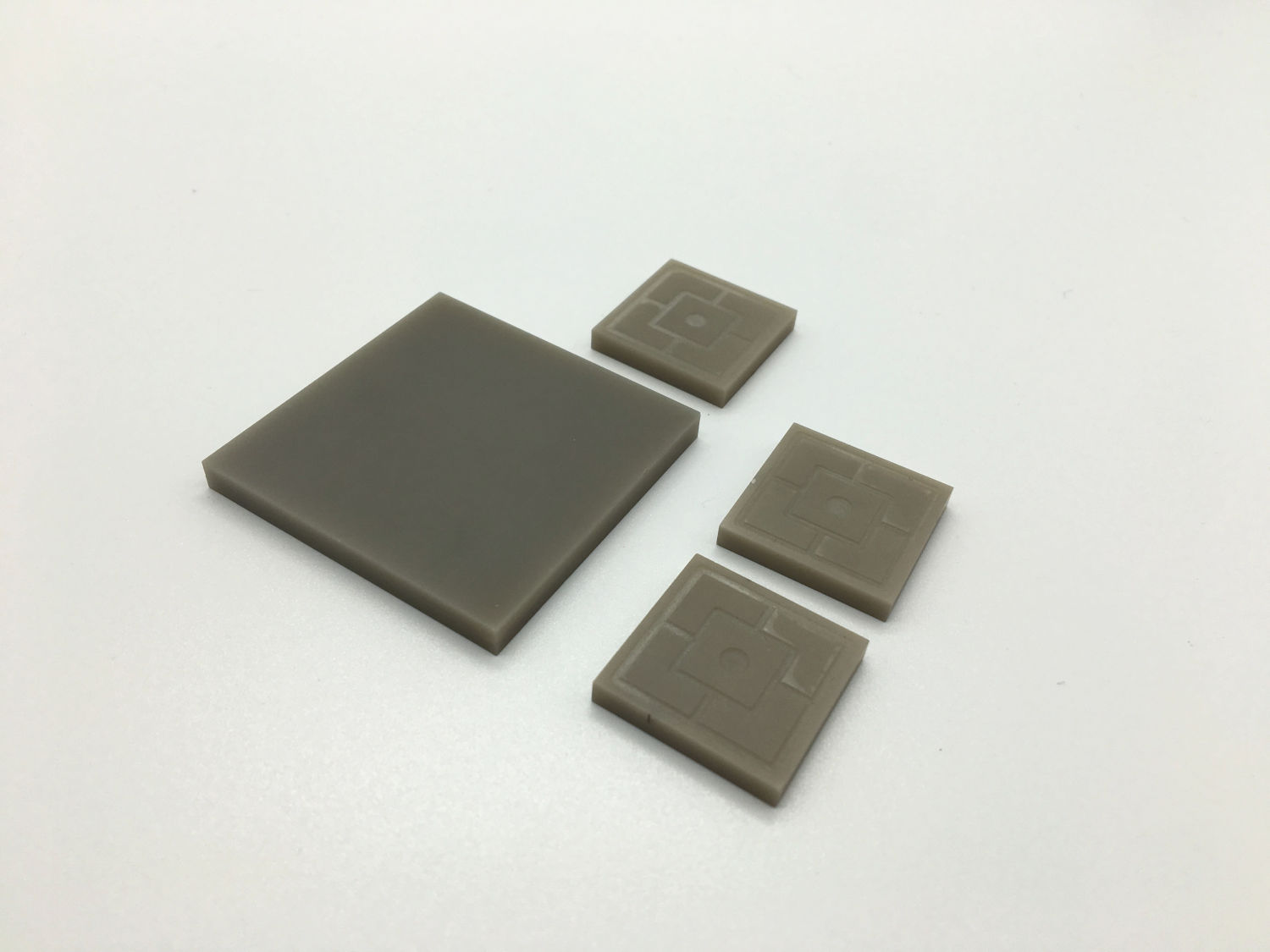

Aluminum Nitride (AlN)

Aluminum nitride ceramic has “extreme” high thermal conductivity, corrosion resistance and low dielectric loss. The coefficient of thermal expansion is close to that of silicon. As a new generation of ceramic materials, the aluminum nitride substrate has good compatibility with circuit materials. It can be used for multilayer wiring which makes it an ideal material for large-scale integrated circuits, semiconductor module circuits and high-power devices.

Applications

- LED solid-state lighting, high-frequency microwave devices, and communication modules;

- Inverters for photovoltaic cells, wind energy generators and new energy vehicles;

- Smelting non-ferrous metal crucibles, evaporation dishes, and magnetic fluid power generation devices;

- High-temperature flattening machine corrosion-resistant parts.

Advantages

- “Extreme” high thermal conductivity

The thermal conductivity of aluminum nitride ceramic is the highest in all ceramic materials; similar to aluminum and more than 6 times higher than Alumina.

- High electrical insulation capacity

Aluminum nitride ceramic has good insulation, low dielectric loss characteristic. Its thermal expansion is close to that of silicon.

- Dense and No toxicity

The aluminum nitride is non toxic and is considered to replace the Beryllium oxide (BeO) in the semiconductor application and substrates.

Technical Characteristics – Aluminum Nitride (AlN)

| AlN | |

| Density(g/cm3) | >3.3 |

| Porosity(%) | 0 |

| Surface roughness (μm) | 0.3~0.6 |

| Warpage(‰) | <2 |

| Elastic Modulus(GPa) | 320 |

| Bending strength(MPa) | ≥450 |

| Thermal expansion(10-6/K) | 2.2~3.6 |

| Thermal conductivity room(W/m•K) | ≥170 |

| Max. use temperature(℃) | 800*(Air) 1300(inert) |

| Volume resistivity (Ω·cm) | ≥1000 |

| Dielectric constant 1MHz | 8~10 |

| Dielectric loss 1MHz | 3*10-4 |

| Breakdown strength(Kv/mm) | ≥17 |

Note: Standard dimension AlN substrates available in stock. Please contact us for more information.