Silicon Carbide (SiC)

Silicon Carbide has been developed to meet a high quality technical grade ceramic with excellent mechanical properties. It is highly wear acids resistant and also showing very high heat resistance, this material is widely used in abrasives, refractories and kiln furniture in extreme conditions.

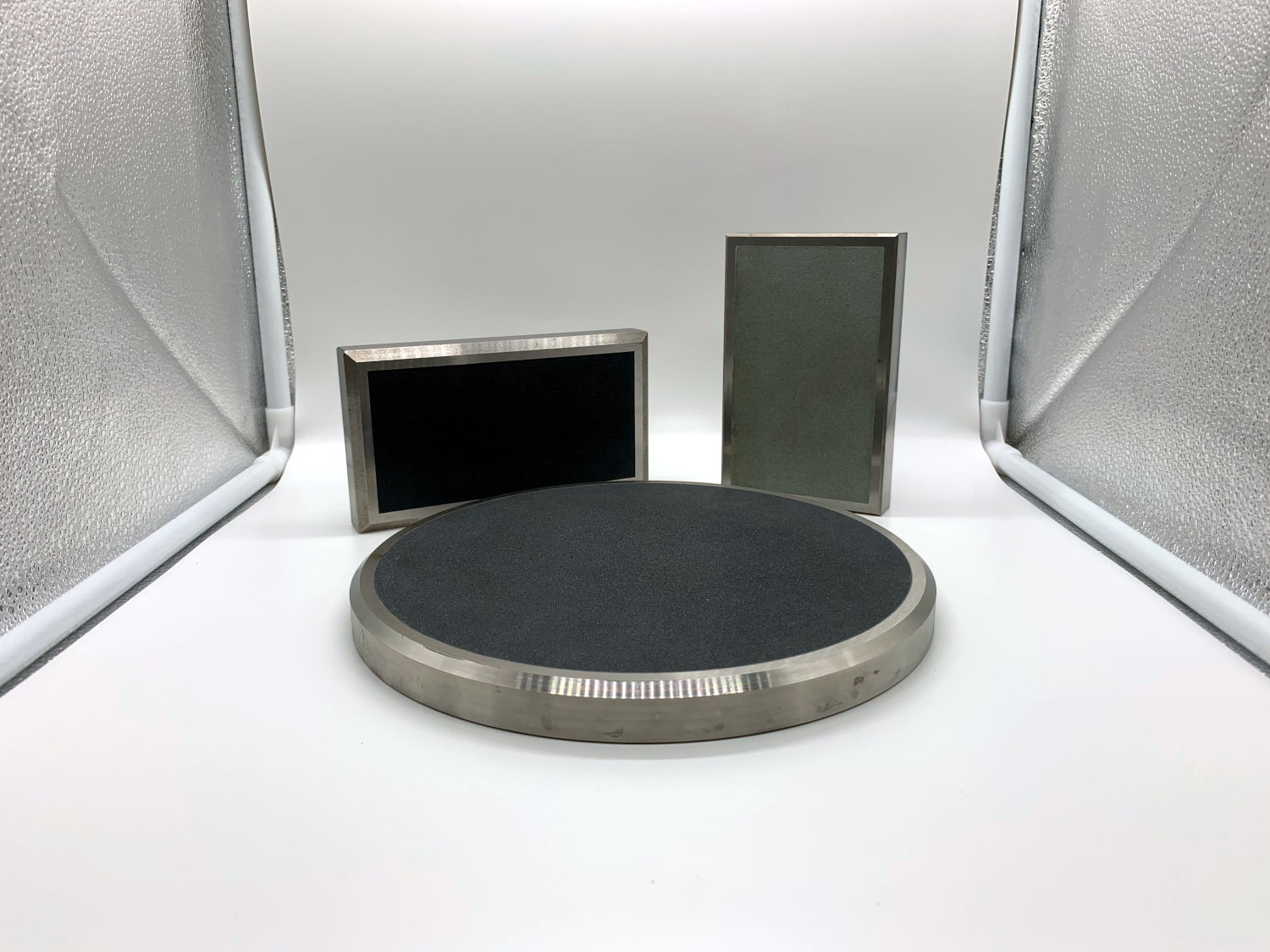

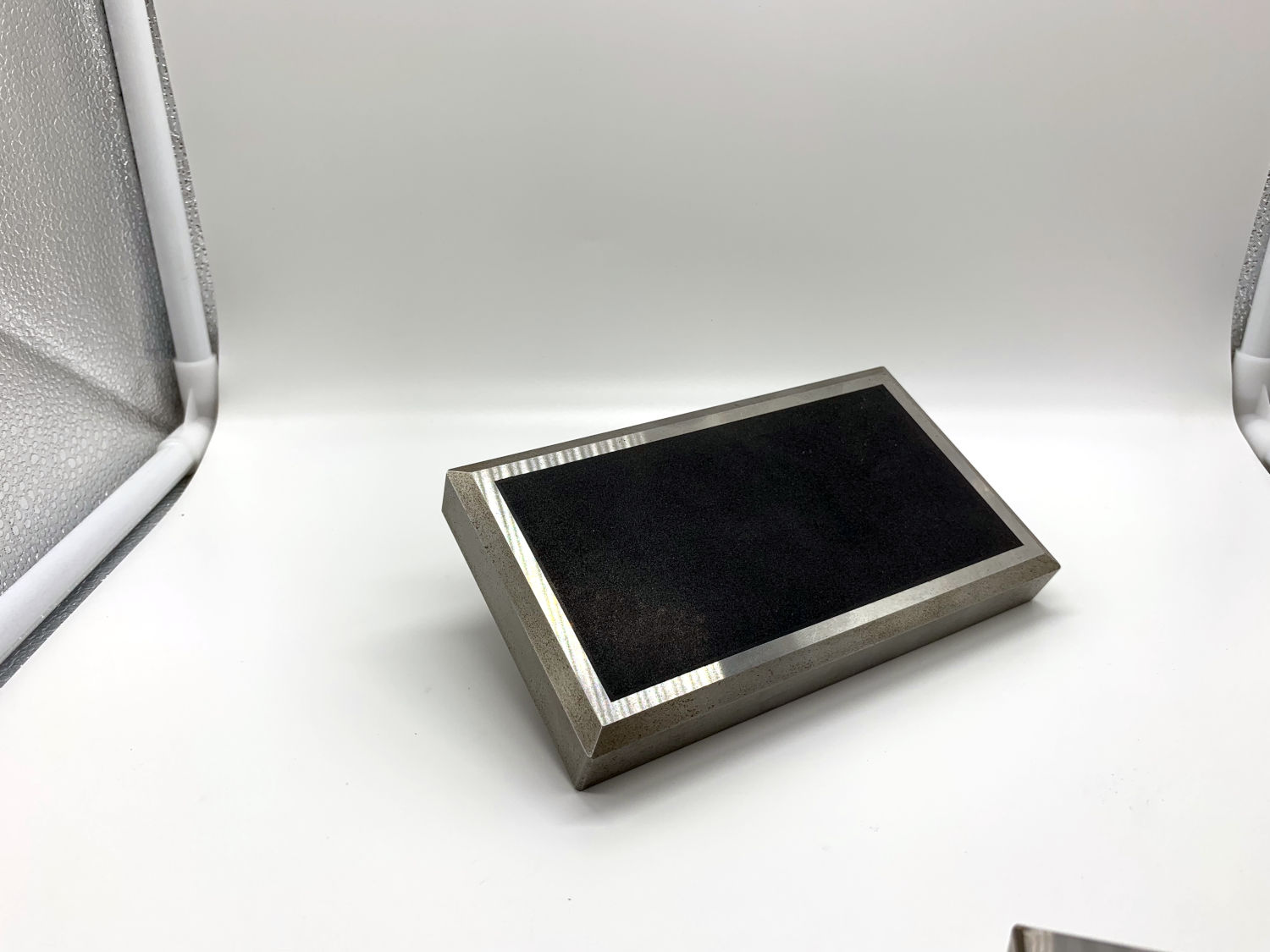

Our silicon carbide products include four series: atmospheric pressure sintered silicon carbide (SSIC), reaction sintered silicon carbide (RBSIC, SISIC), recrystallized silicon carbide (ReSIC), and silicon nitride bonded silicon carbide (NSIC).

Applications

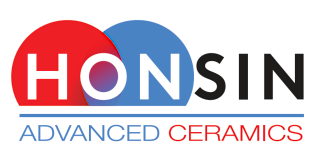

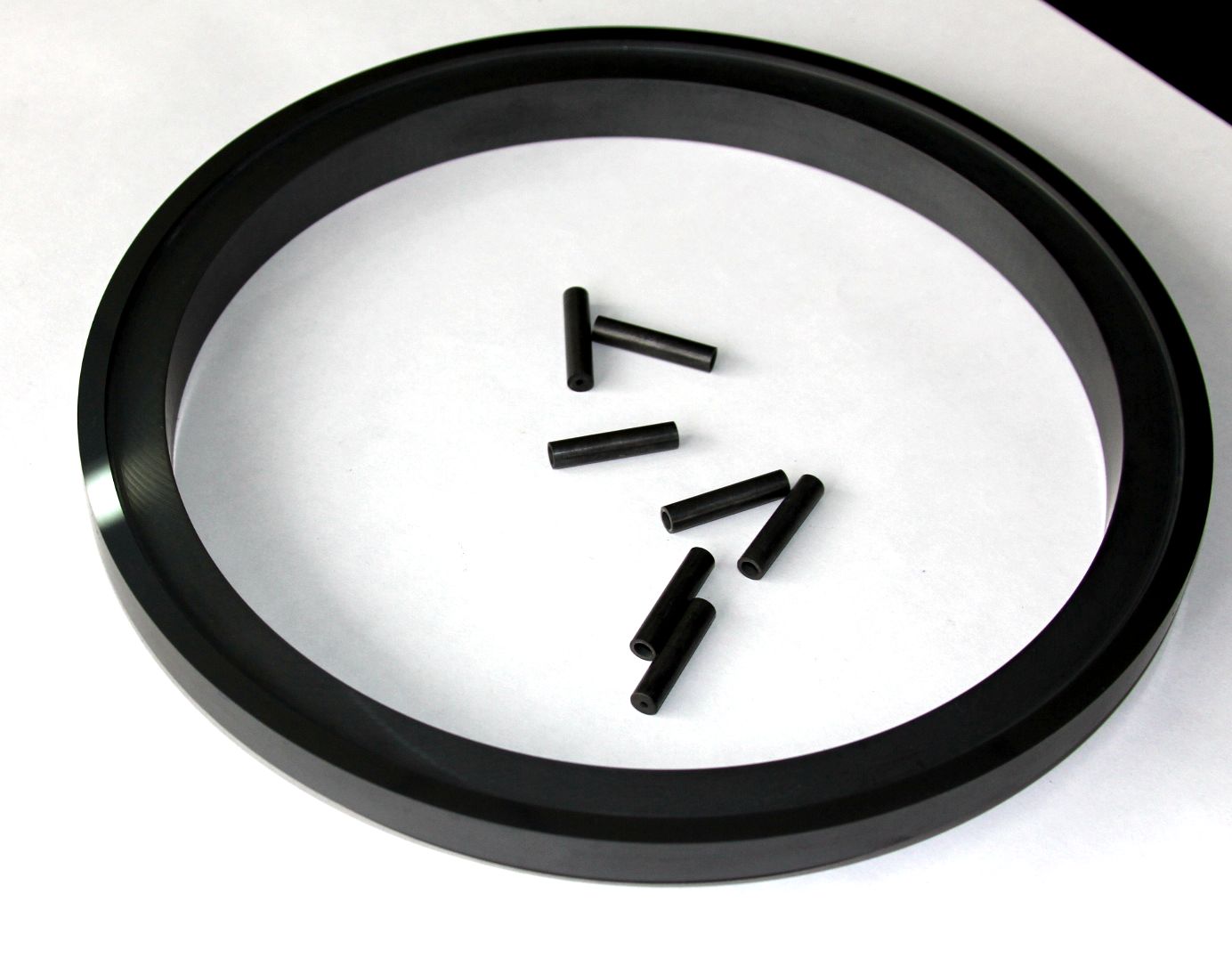

- SSIC is mainly used to manufacture sealing rings, shaft sleeves, high-temperature nozzles, kiln furniture, bulletproof sheets, corrosion-resistant devices etc.

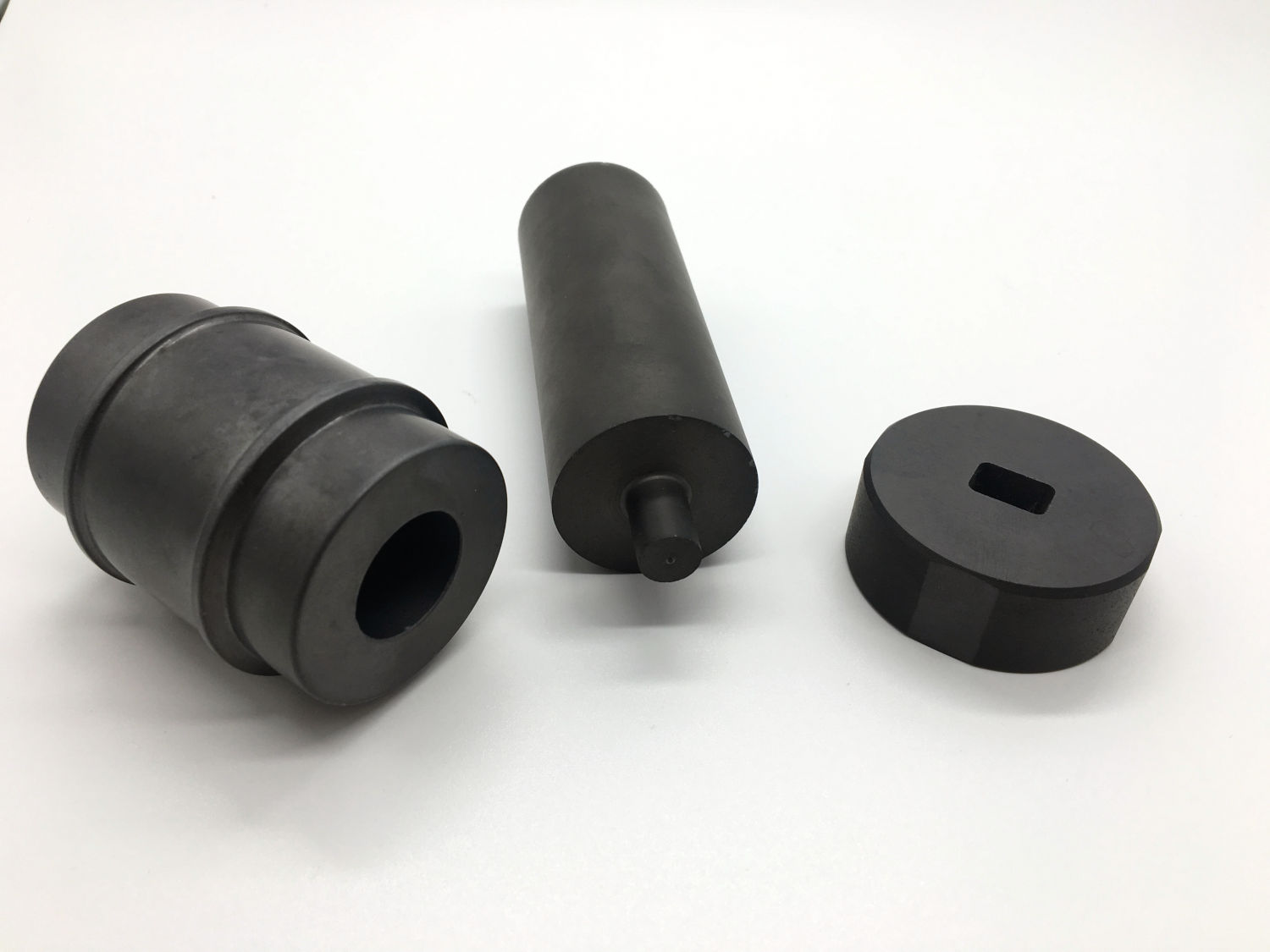

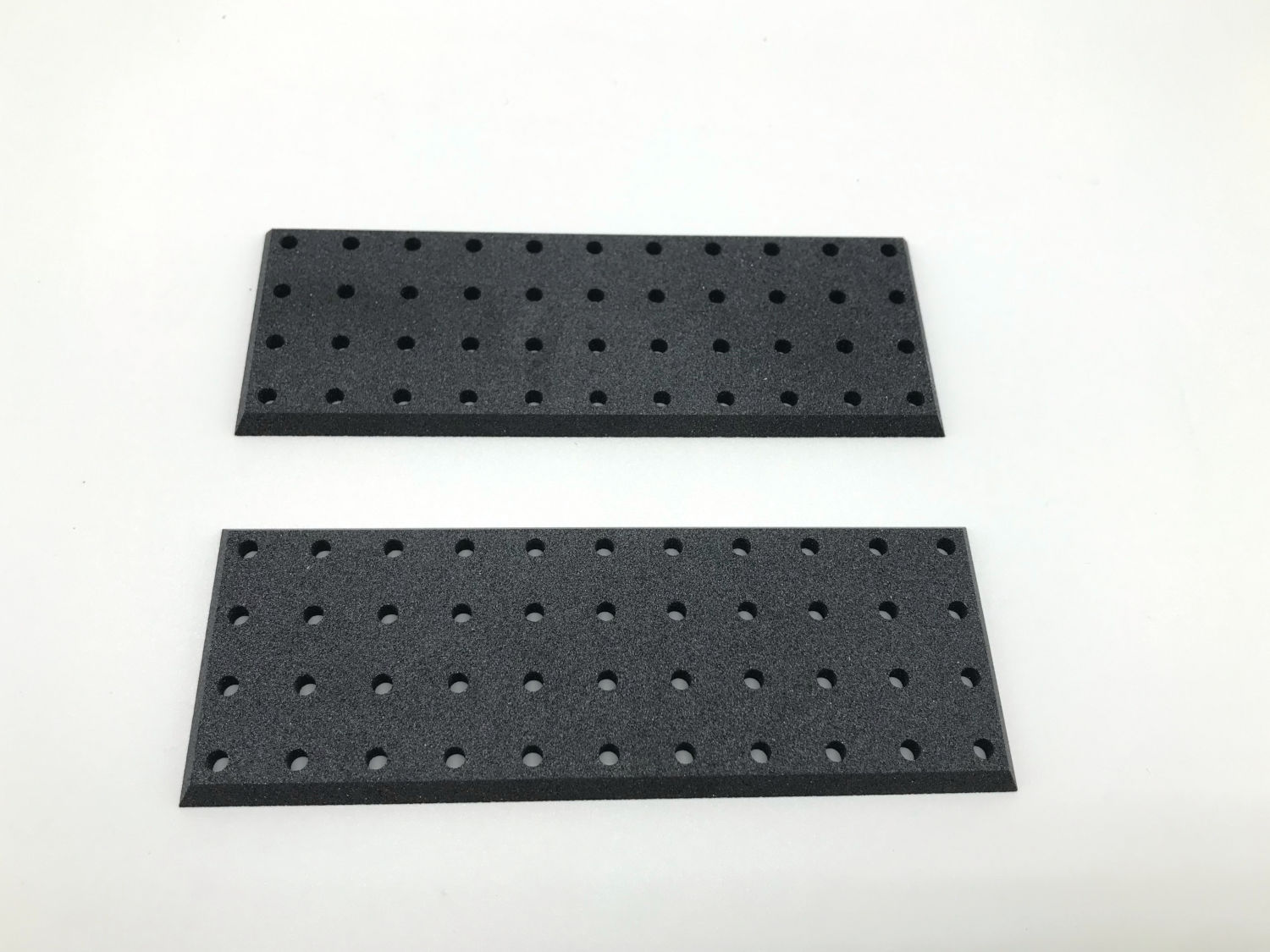

- SISIC is mainly used in the manufacture of kiln beams, roller rods, flame nozzles, flame distributors, cold air ducts, burner plates, diffusion tubes, catalysts, and protection Tube etc.

- ReSIC is mainly used to manufacture kiln furniture such as beams, shed boards, fish plates, roller bars etc.

- NSIC is mainly used to make crucibles, fish plates, molten metal handling, melting sinkers etc.

Advantages

- No deformation at high temperature

Silicon carbide ceramic has excellent mechanical properties even at high temperature. It’s one of the most popular for sealing, support parts for long-term stable work.

- Constant performance at high temperature

High strength and corrosion resistance which stay constant up to very high temperature of (1600 °C). It’s one of the materiel choice for refractory and chemical resistance applications.

- Excellent hardness

The hardness of our Sintered Silicon Carbide is near to diamond.

Technical Characteristics – Silicon Carbide (SiC)

| SSIC | SISIC | ReSIC | NSIC | |

| Density (g/cm3) | 3.1 | 3.0 | 2.7 | 2.78 |

| Porosity (%) | <0.1 | <0.1 | 15 | 10 |

| Elastic Modulus (GPa) | 420 | 330 | 240 | 240 |

| Bending strength (MPa) | — | — | 90 | 165 |

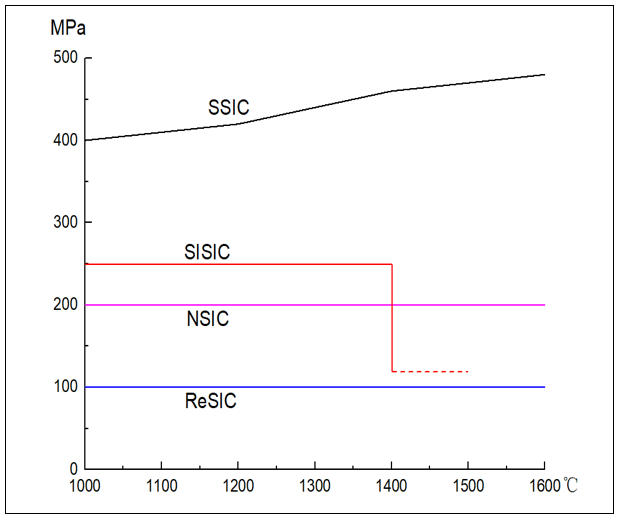

| Flexural strength Room (MPa) | 400 | 250 | 100 | 200 |

| Thermal expansion (10-6/K) | 4.1 | 4.5 | 4.8 | 5.0 |

| Thermal conductivity (W/m•K) | 70 | 160 | 24 | 15 |

| Max. use temperature (°C) | 1600 | 1380 | 1650 | 1550 |

4 points bending strength

Corrosion Situation

| Environment | Temp. (℃) | SSIC (mg/cm2) | SISIC (mg/cm2) |

| 98% H2SO4 | 100 | 1.5 | 50 |

| 50%NaOH | 100 | 2.5 | >1000 |

| 53%HF | 25 | <0.2 | 7.0 |

| 85%H3PO4 | 100 | <0.2 | 8.0 |

| 70%HNO3 | 100 | <0.2 | 0.5 |

| 45%KOH | 100 | <0.2 | >1000 |

| 25%HCl | 70 | <0.2 | 0.9 |