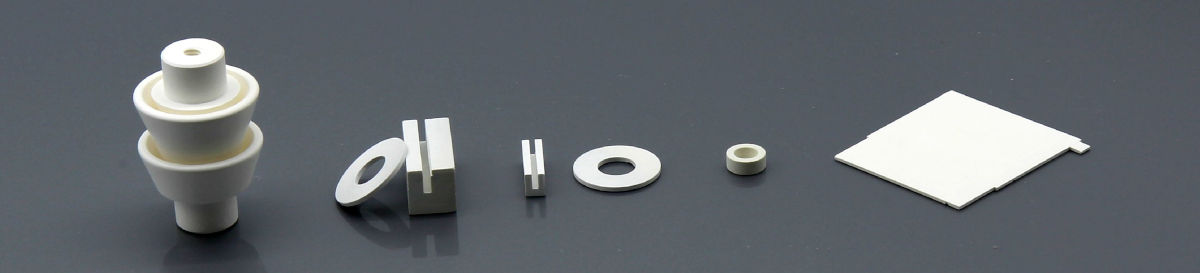

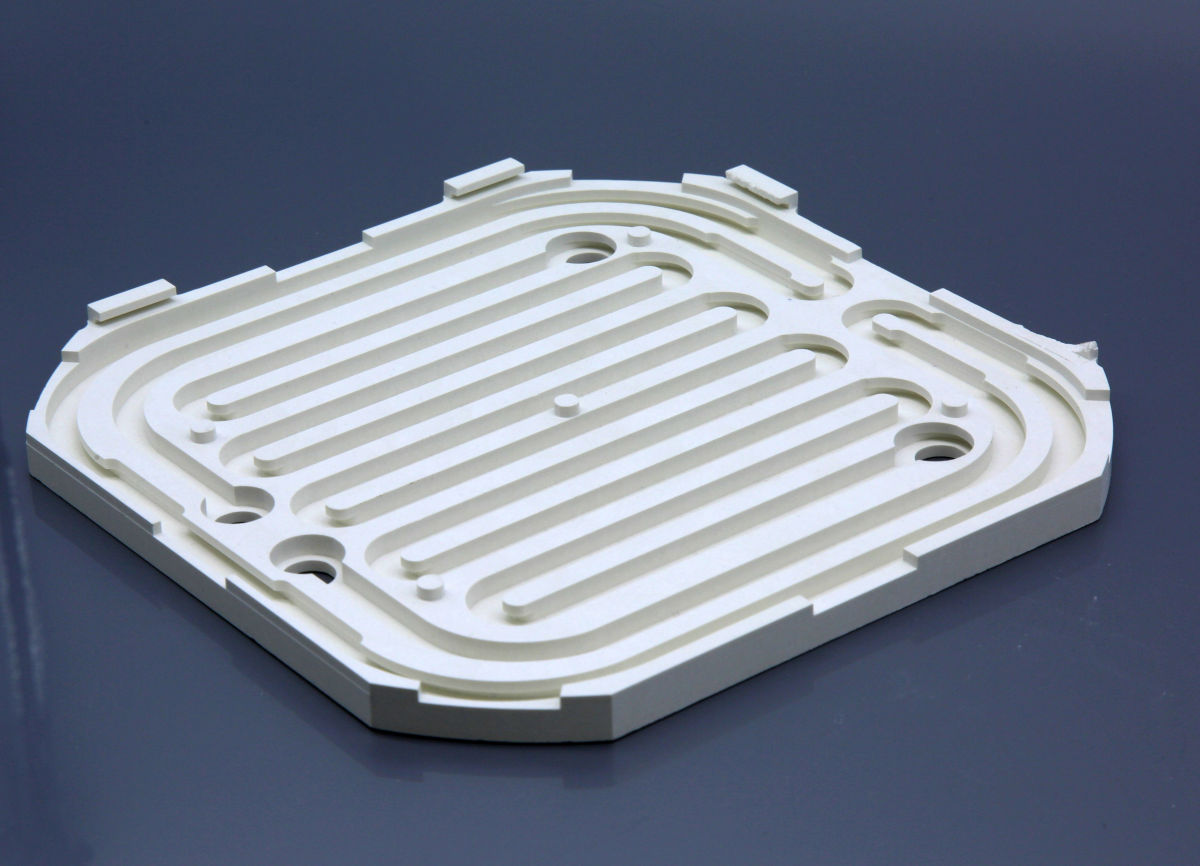

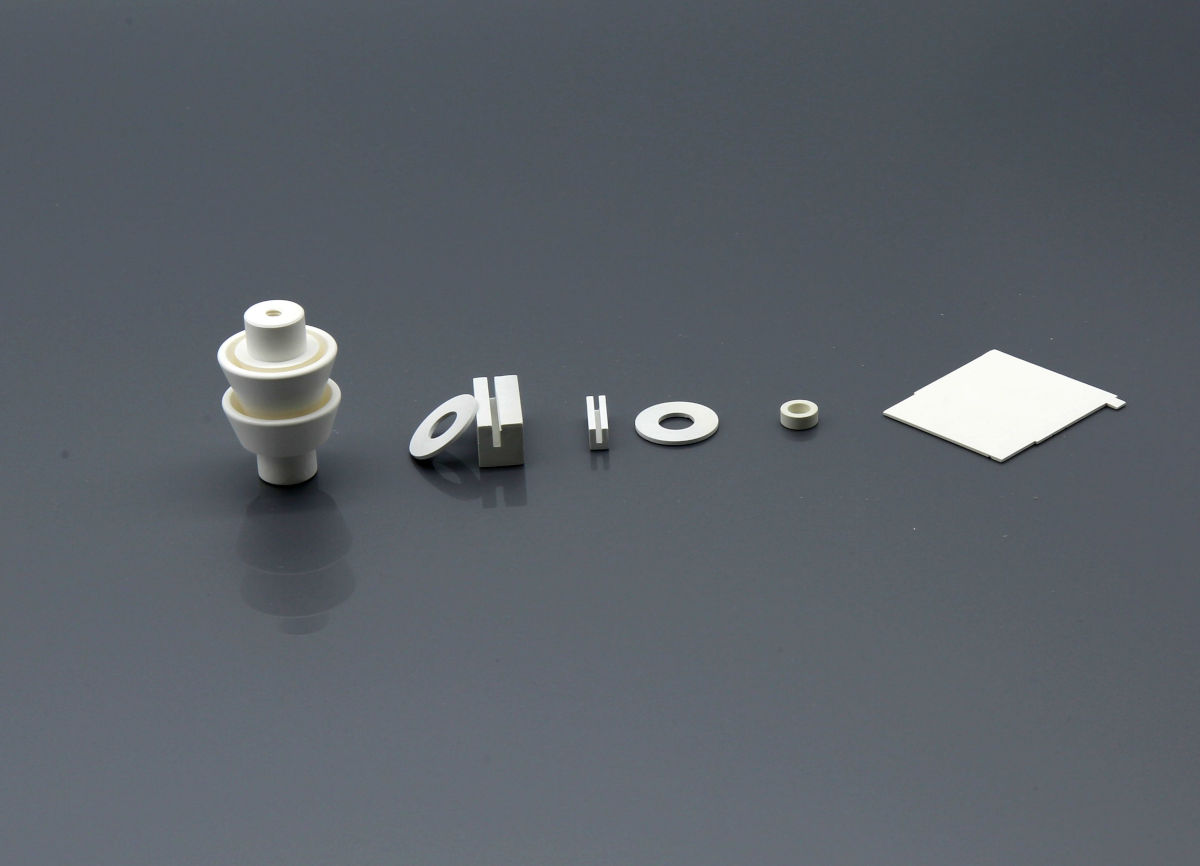

Boron Nitride (BN)

Hexagonal boron nitride ceramics have excellent properties in chemical, electrical, mechanical and thermal. It’s used widely in the fields which request high performance ceramics. Honsin Boron nitride (hBN) offers excellent characteristics in extreme conditions.

Honsin Ceramics is able to provide composite Boron Nitride solutions for the customers with specific characteristics.

Our hBN series products can resist temperature above 1800 °C in vacuum or inert atmosphere. It’s an important part of high temperature vacuum furnace and atmosphere furnace.

Applications

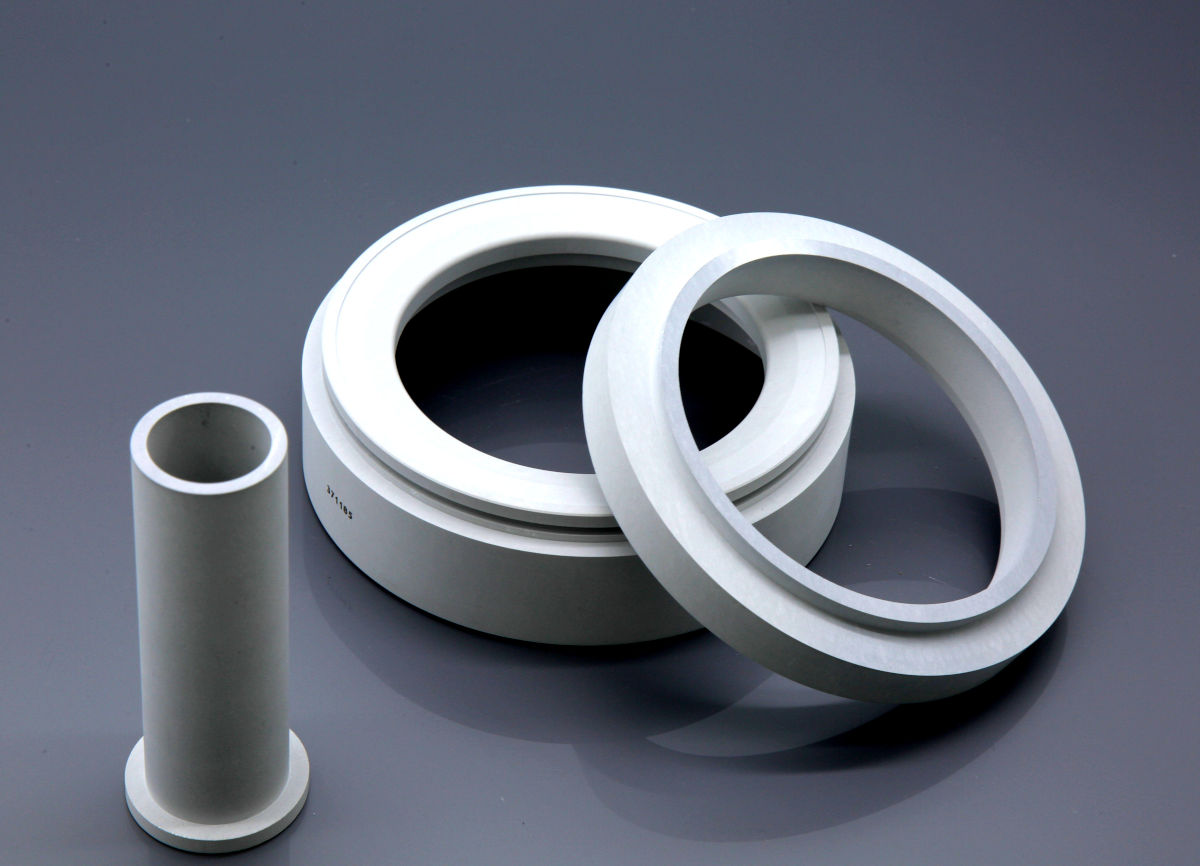

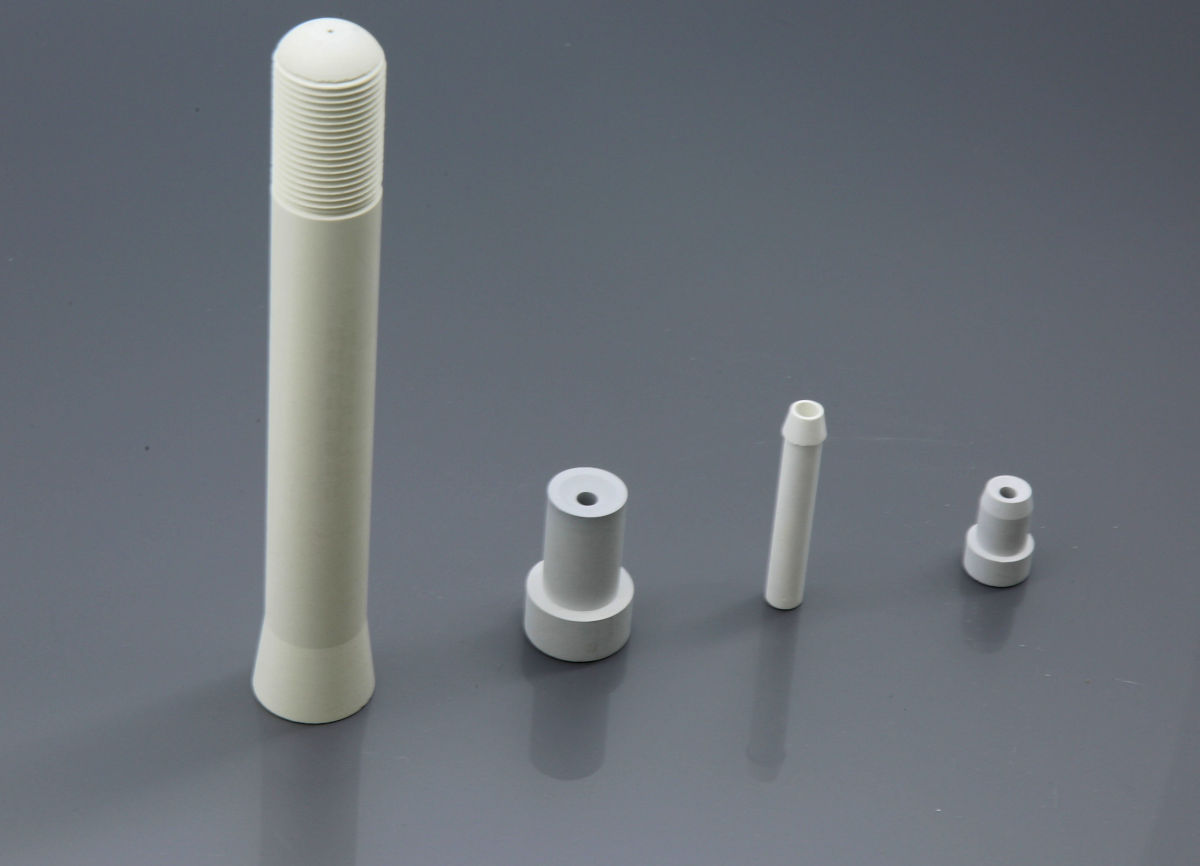

- Metal casting & Powder metal metallurgy: Supersonic atomization spray nozzle, lifting nozzle, casting separation ring, crystallization tube, molten metal handling

- Vacuum furnace accessories: Surface coating PVD and plasma systems, seal rings, ceramic screws, insulation gaskets, etc.

- Others: Semiconductor components, ion implanter insulation parts, amorphous soft

Advantages

- High temperature insulation

BN can provide long term use experience at above 1800°C at vacuum or inert atmosphere and keep high electrical breakdown strength

- Corrosion resistance

BN exhibits outstanding acid, alkali corrosion resistance and carbon erosion resistance which make it one of the most stable ceramic

- Exceptionnel thermal shock resistance

BN has exceptional high thermal shock resistance — making it ideal for applications with high dynamic stresses, thermal rigor, and demanding reliability requirements

- Composite Boron nitride

Honsin Ceramics is able to offer various types of Boron nitride (composite) in order to select the best overall thermal, electrical and mechanical performance. Therefore to improve constantly user experience in a very demanding environment

Technical Characteristics – Boron Nitride (BN)

| Grade | HS-BN | HS-BNCA | HS-BNAL | HS-BNZR | HS-BNALN |

| Composition | BN>99% | BN>97.5% | BN+Al | BN+ZrO2 | BN+AlN |

| Color | White | White | Gray | Gray | Gray-green |

| Density(g/cm3) | 1.95 | 2.0 | 2.30 | 2.9 | 2.65 |

| Resistivity(Ω•cm) | >1014 | >1014 | >1013 | >1012 | >1013 |

| Max. temp.(℃) Atmosphere Inert gas Vacuum | 900 2100 1900 | 900 2100 2000 | 1000 1700 1700 | 1000 1800 1800 | 1000 1800 1800 |

| Flexural strength *(MPa) | 30 | 35 | 85 | 120 | 90 |

| Compressive strength *(MPa) | 55 | 70 | 145 | 200 | 220 |

| Expansion coefficient *(10-6/K) | 1.5 | 1.6 | 1.9 | 3.5 | 2.8 |

| Thermal conductivity *(W/m•K) | 30 | 32 | 35 | 30 | 85 |